DRUPA is the biggest trade fair for Print and Paper (DRUck und PApier) in the world. It usually happens every four years, but due to the pandemic this was the first one in eight years.

There is no denying that the industry sector is contracting, the show had less exhibitors and the number of visitors went down by a third (260.000 in 2016, 170.000 in 2024).

There was a lot of diversity in ethnicity and colour, a little bit in age – but gender not so much. Seems like the decision makers in the print companies are still mostly mature males.

However, those who made it there seemed upbeat and there was news of many investments made already at the show. There are special show offers, as vendors want to display the “Sold to “ sign on their engines.

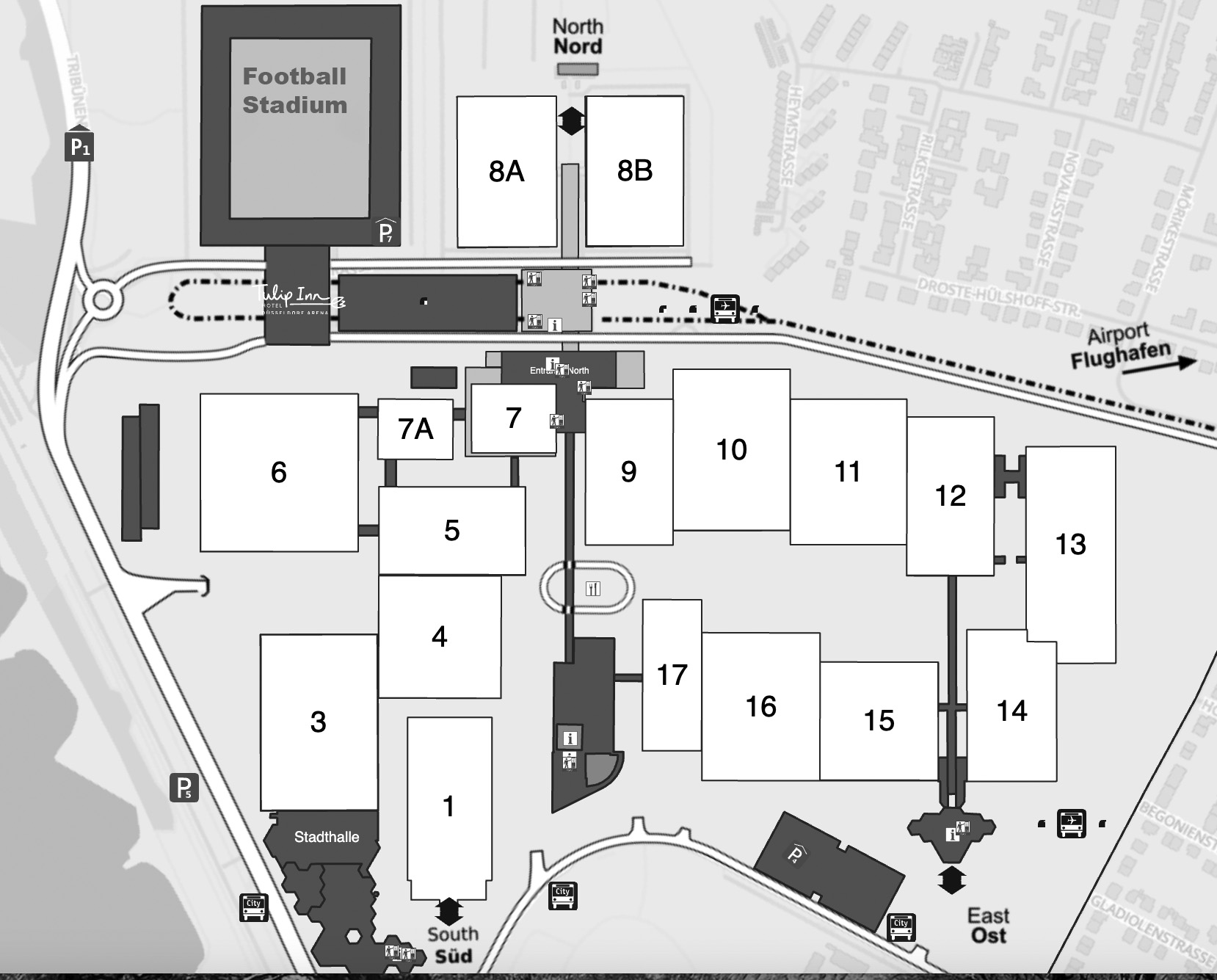

The trade fair still occupied all 18 halls of the Dusseldorf Messe, over 150,000 sqm of exhibition space, a massive area with close to 40km of aisles, compare size of the Euros football stadium upper left of the map.

There were a lot of Australians already in the first week and the social gathering for Australian and NZ visitors on Friday evening was sold out.

The biggest exhibitor this DRUPA was Hewlett Packard, occupying the whole of hall 17. Heidelberg, who used to dominate the show in the past, were still in Hall 1 with some big offset presses, but overall, digital print dominated.

HP had a very lively area showing a plethora of new Indigo and Pagewide inkjet presses. Focus was on productivity in publication and marketing print and on solutions for packaging and labels. The formerly biggest US printer RR Donnelly bought 15 Indigo presses at the show.

Apart from many new machines, HP also announced an alliance with Canva and FIVRR at the show, providing links to their digital printer network for Canva customers to get their designs printed across the world from their desktop. HP has a history of offering solutions to end users like designers and publishers, however they don’t always succeed (remember Piazza?).

We visited the other big digital print engine suppliers: Canon had a massive stand, showing their production print and large format engines. Canon are still leading in the small format (up to A3+) inkjet space with their iX series and sold several machines at the show (two to CMYK Hub). Canon showed videos of their upcoming A2 size inkjet and took customers to their production site across the Dutch border in Venlo to see a prototype. They also showed the new version of their web fed Colourstream press, producing more than 100.000 images per hour in offset quality.

A2 size inkjets were prominent at the show, with new models form Fujifilm, Canon, Ricoh and others. These presses are designed to be installed in the currently still very large user base of half size offset presses, instead of a new offset press. This represents a significant market with many print businesses looking at having to adjust to changing conditions and client demands. Canon announced an agreement with Heidelberg, who are now selling inkjets under their jetfire branding, addressing their large offset user base. Heidelberg showed the integration of the Canon product into their Prinect workflow, where a “pathfinder” selects the best engine for each job, be it toner, inkjet or offset.

Ricoh were showing new editions of their toner presses as well as their web fed inkjet press. Fujifilm showed their recently launched B2 toner press, the only one at that size, which is usually served by Indigo and inkjet presses.

Looking at the samples from the digital presses, there is no obvious quality difference to offset for most print users, and the range of substrates has also extended greatly. Pricing is a big difference, though, and especially the variable page cost on inkjets could still be challenging for printers investing into digital.

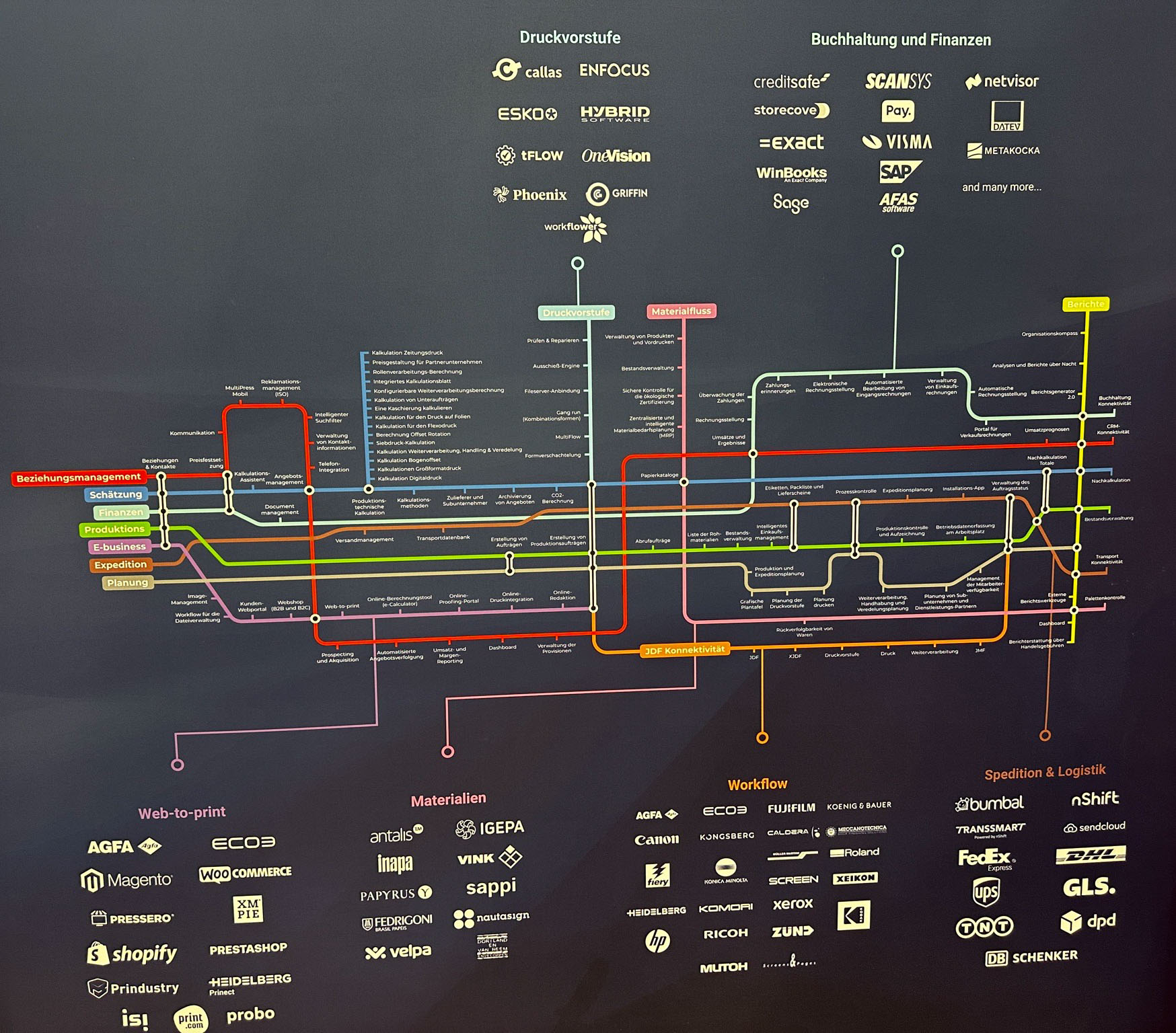

Software

Traditionally Hall 7 was the area for software vendors, but now software is everywhere and vendors of workflow software, MIS systems, and Web to Print systems can be found in many halls. Hall 7 now hosts the smaller companies and startups. It also has a presentation area with talks by vendors and industry experts.

Below is the founder of Printess software holding a talk: “Every print company is an IT company”, highlighting the importance of IT in a manufacturing organisation and the challenges IT presents.

Printess showed personalisation engine that plugs into web to print systems. It is very fast, as most calculation happens locally in the browser. They are not new to this area, having developed Direct Smile in the 2000s, before selling it to EFI. In 2022, EFI sold its software business, which became EProductivity Software. EPS software own the widest variety of MIS systems for the industry, from Prism, Pace, Technique and Monarch over to recently acquired Tharstern, and the newly developed Nubium. Nubium was built from scratch as a cloud based MIS aimed at the thousands of small to medium sized print companies. We met Nick Benkovich, an Australian industry veteran who knows systems, workflows and also everyone in the industry. We discussed EPS’s solutions for print management companies.

Many of the new and updated MIS systems focus on automation and there are early signs of the use of AI in workflow and admin. Simple example: to create an estimate you can just drop a pdf and the system analyses the file, asks for the desired quantities and presents a quote, suggesting substrates and machines to use. But this is still only machine learning, and there was no evidence of systems improving as they go and learning from requirements and from a feedback loop with wins and losses of quotes.

Automation in asset management and pre-engine workflow was also a big topic, with preflight, personalisation, routing of files and passing meta information and specifications to print engines and finishing devices without the need for human intervention. Examples were book production lines that automate machine setups and enable practical and economical ultra short runs and PoD.

Fujifilm showed a new workflow solution that is vendor agnostic and delivers files and exchanges information with print engines and finishing devices for multiple vendors.

While robots in the past had been mostly used in raw material movement, they now are capable of a wider variety of tasks, moving pallets, running finishing equipment and binding books, assisted by machine learning and AI.

In summary, Drupa was a great show, a concentration of who and what moves the industry. There were new machines and software solutions, although some of the bigger machines shown will never make it to a small market like Australia. There were advances in technology that will filter through to print shops globally, and a hunch of what is to come with the penetration of AI into every area of business.

A trade show like DRUPA certainly needs to re-evaluate its purpose to stay valuable, it is expensive and restrictive compared to online events, but there were people meeting people, talking about common interests, and the general feel was that the industry is very alive. And that has value.

Thanks for sharing this Michael. As a fellow print nerd I’m having DRUPA-envy.

I’m very curious to see how book printing continues to evolve in the face of declining print volumes or a greater spread of small volumes across a seemingly infinite catalogues of millions of titles.